Adapted from the article “Irrigation System Maintenance” by Dani Lightle, UCCE Glenn, Butte & Tehama Cos. and Kevin Greer, TCRCD Mobile Irrigation Lab, from the October 2014 Sacramento Valley Prune News.

Maintaining uniform distribution of irrigation water is critical for optimizing irrigation efficiency and scheduling. High distribution uniformity (DU) ratings indicate even water supply across the orchard, critical to ensuring all trees receive similar quantities of water. Low DU results in simultaneous over- and under-irrigation occurring across the orchard block, higher water use to meet the demands of every tree, and unnecessarily long pump run times. Elements that contribute to high DU are balanced pressures, matching sprinkler types and nozzle sizes, and system maintenance.

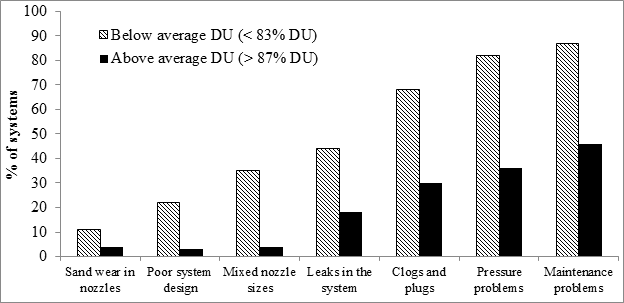

Poor maintenance is one of the leading causes of low DU. Greater than 80% of the systems evaluated by the Tehama County Mobile Irrigation Lab between 2002-2013 with below average DU had pressure and/or maintenance problems (Figure 1). Of the systems with above average DU, nearly half still had maintenance issues that could be corrected to further improve their DU. System maintenance is an essential component of an efficient irrigation system that is easy to overlook amid the numerous demands required to run an effective growing operation.

Figure 1. Problems identified in 209 micro-irrigation system evaluations between 2002 and 2013 in the Sacramento valley. Data courtesy the TCRCD Mobile Irrigation Lab.

It is best to purposefully schedule system maintenance during the intensive irrigation season. All types of irrigation systems can benefit from maintenance, although the intensity and amount of time required varies pointedly by irrigation system type. While micro and drip systems tend to be the most uniform in application when well maintained, the amount of attention they require to run at optimal levels is substantially higher than other systems. Regardless of the system, adopt routine maintenance practices.

Irrigation Pump

- Clean primary filters (at the pump) and any secondary filters (often located in the field). Backwash to remove organic or particulate matter. If using a sand media filter, check that sand is not caking and replace what is lost in backwash cycles. Be sure you have installed the correct type of filter for the type of debris in your water source.

- Pressure gauges should be installed before and after filters. If there is a 5 to 7 psi difference between the two gauges, check for filtration plugging. Replace gauges (about $15) approximately every 3 to 5 years because reliability decreases in aging gauges.

- Ensure that pressure regulating valves are accurately providing the desired pressure by checking against a quality new pressure gauge.

Micro & Drip Systems

- Systems should be inspected at every irrigation event for plugs and leaks in the lines. Any lines that have leaks should be repaired by splicing the lines together. Tape will not work, and plugs will increase the size of the hole or crack over time.

- Check for clogged nozzles with a flow test for reduced output. If changing nozzle heads, ensure you are replacing with nozzles of the same size. Check drip emitters for clogs and examine around emitters for bacteria or calcium build-up. Depending on the type of clogging, chemical treatments may be needed.

- Plugs can be a significant problem at inlet screens. The type and quantity of debris may indicate a problem with filtration effectiveness at the pumping station, which may need an upgrade. If plugs are a consistent problem, some growers remove the screens. If you remove screens, hose line flushing and checking for plugged emitters should be done more frequently.

- Flush the lines approximately every other week and after chemigation and fertigation applications. Begin with the mainlines, followed by submains, then laterals. Check the clarity of the water on the lines that are hydrologically farthest from the pump station. If water flushed from the lines is dirty, lines need to be flushed more frequently; if water is clear, the current flushing schedule is sufficient.

- Emitters should be run at the pressure ranges listed in the manufacturers’ specs. If pressures are too high or too low, the distribution patterns, flow rates, and overall operation is no longer functioning as designed. Pressure regulators maintain uniform pressures to each inlet. If the pressure leading into the regulators is too low, the regulators will not operate and emitters will not function correctly.

Go here for further troubleshooting help for common problems such as clogging.

Solid Set Systems

- Compare the flow rates of your sprinklers to the manufacturers’ specifications to determine if sand wear is contributing to worn nozzles. Check nozzles after 5 years and monitor thereafter. When replacing worn nozzles, replace with the same type and model. Replace nozzles in the entire orchard on a regular schedule because new nozzles will have different flow rates compared to old ones.

- Following each irrigation, open the flush out valves at the ends of main and submain lines and leave open until water runs clear. If heavy sand is consistently being flushed, there may be problems with the effectiveness of the pump station filter.

Flood and Furrow Irrigation

- Ensure that borders are not leaking or seeping into the neighboring dry checks. This occurs as a result of erosion over time. Check for high or low spots within the check and level as needed.

- Verify there is no erosion around the head above the check valve and repair as needed.

Leave a Reply