Allan Fulton, UCCE Irrigation and Water Resources Advisor, Tehama, Shasta, Glenn & Colusa counties; Luke Milliron, UCCE Orchards Advisor, Butte, Tehama & Glenn counties; and Richard Buchner, UCCE Farm Advisor Emeritus, Tehama county.

Consistency begins with using the same operator!

Consistent technique helps improve the accuracy of SWP measurements. On the same almond trees, as much as a 2-bar discrepancy, plus or minus, has been documented with different operators. Such errors can be due to differences in speed and method of handling the sample from the time the leaf is excised until the measurement is completed, or they can be due to differences among operators in recognizing the endpoint. Having different pressure chamber operators is frequently cited as the greatest source of SWP reading variability. Relying on one operator to check the same orchards over the season, using the same pressure chamber and consistent technique is highly recommended.

Proper bagging of leaves for SWP

Good SWP measurement technique begins with properly selecting sample leaves and bagging or covering them with a foil-laminate bag (fig. 1). Leaves should be healthy, full grown, and without physical damage from wind or hail. Lower interior, shaded leaves are selected nearer to larger branches of the tree. These bagged leaves equilibrate readily with the tree’s main water-conducting system. Leaves higher in the canopy or farther out on a limb can give significantly different levels of SWP. Reflective, water-impervious Mylar foil bags are commonly used for bagging leaves. Bags are available from some pressure chamber manufacturers. Nylon velcro fasteners, resealable zip fasteners, paper clips and other creative approaches can be used to fasten the foil bags to the leaves.

Figure 1. From left to right, healthy, full grown leaves are selected in the lower interior canopy of an almond, prune, and walnut tree near larger branches and covered with mylar foil bags for at least ten minutes. Walnut has a compound leaf, so the terminal leaflet is selected because it has a longer petiole which assists the measurement. (Photos: A. Fulton)

The importance of bagging or covering the sample leaves on large perennial trees can’t be emphasized enough. Ideally, the sample leaves are bagged for at least 10 minutes prior to excising the leaf from the tree. It is acceptable to bag leaves longer than 10 minutes. They may be covered several hours or even a day in advance if it adds convenience.

After the trees with the sample leaves have been bagged for at least 10 minutes, it is time to measure the SWP with a pressure chamber. The leaf must remain enclosed in the bag after it is excised from the tree and placed in the chamber. If the bag is removed at any time, the SWP level will begin to change rapidly (within seconds) as the leaf is exposed to the often hot, windy environment around it. Only using bagged leaves is an important practice in acquiring stable, more-representative measurements that are easily interpreted. Resist the temptation to remove the leaf from the foil bag even if it makes inserting the sample leaf into the chamber easier.

Proper measurement technique

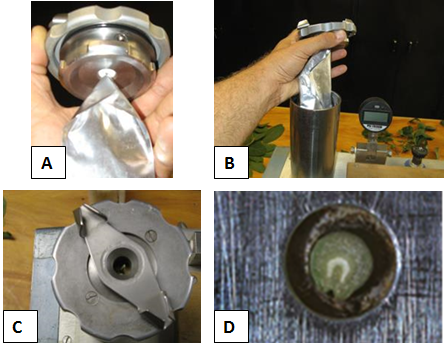

Measuring SWP (fig. 2) after the bagged leaf is excised from a tree involves inserting the stem of a bagged leaf upward through the top of the pressure chamber and securing the protruding stem in the pressure chamber cap (A). Then, placing the bagged leaf in the pressure chamber (B). A long stem is shown protruding out of the top of the chamber (C). Some researchers emphasize that the stem should not be protruding out this much for the most accurate measurement of SWP. Other researchers have observed that practitioners have more difficulty seeing the endpoint without the longer stem, which can also introduce error in seeing the endpoint. Apply pressure inside the chamber and determine the endpoint for a SWP measurement. Close to the endpoint, water begins to exude from the surface of the cut stem and will appear to glisten (D). With the addition of a little more pressure, water will cover the entire cross-section of the stem and reach the endpoint. When this endpoint is observed, stop adding pressure to the chamber and read the gauge.

Figure 2. Basic process of measuring midday SWP with a pressure chamber. (A) Bagged leaf is excised from the tree and the stem is inserted through the pressure chamber cap. (B) Bagged leaf is placed into the pressure chamber. (C) A long stem should protrude through the top of the chamber. (D) Water will exude from the surface of the cut stem and the surface will glisten when the endpoint is reached. Photos: A. Fulton and K. Shackel.

Most pressure chambers (excluding hand-held pump-up models) incorporate an adjustable metering valve to regulate how fast pressure builds inside the chamber. Metering valves should be set to increase pressure slowly to lessen the chance of missing the endpoint. Operators should set the rate the chamber pressurizes slow enough so that it is possible to both watch for the endpoint and read the pressure gauge at the same time. Experience suggests that a pressure increase of 0.25 to 0.5 bars per second is just about right.

Advanced technique

In both gas tank and pump-up models, once the end point is reached or accidentally exceeded the operator can release a small amount of pressure (0.5 – 1 bars) in-order to check for the correct endpoint. Once pressure is released, the operator can wipe off the moisture on the cut petiole with their finger and wait several seconds for the bubbling to subside. They then slowly re-pressurize looking closely for the correct endpoint.

SWP measurements should be completed as rapidly as possible after bagged leaves are excised. It usually takes an experienced operator 15 to 30 seconds to take a measurement depending on the plant water status. To minimize variability, readings should be made within 1 minute of being removed from the tree.

Most pressure chambers (excluding hand-held pump-up models) incorporate an adjustable metering valve to regulate how fast pressure builds inside the chamber. Metering valves should be set to increase pressure slowly to lessen the chance of missing the endpoint. Operators should set the rate the chamber pressurizes slow enough so that it is possible to both watch for the endpoint and read the pressure gauge at the same time. Experience suggests that a pressure increase of 0.25 to 0.5 bars per second is just about right.

Video Tutorials

Below are two videos that should help develop your measurement technique:

This 10-minute video by Allan Fulton demonstrates how to measure SWP in almonds, one of the more challenging crops because of its smaller leaves and petioles. At the 6:55 mark, the video shows a magnified view of the endpoint of a measurement.

This 10-minute video by Professor Ken Shackel, Plant Sciences, UC Davis, demonstrates the behavior of the endpoint when using a pressure chamber to measure stem water potential. A microscope is used to magnify the demonstration.

Note: This is the fourth article in a series on stem water potential. Access previously posted articles here. This series is an an abbreviated discussion based upon peer-reviewed UC ANR Publication 8503, Using the Pressure Chamber for Irrigation Management in Walnut, Almond, and Prune (2014).

Leave a Reply