Technology vs Confusion

“Technology” has different meanings for different people (Figure 1). In irrigated agriculture we look towards technology to meet our changing needs and sustain our industry in the long run. However, with technology, “confusion” and a sense of overload can hinder our ability to learn and apply it. This article considers the abundance of irrigation technology and the challenges with its adoption. Some ideas are offered to cope with the sense of confusion and overload.

Why and Why Not Technology?

On one hand, there are many drivers that can cause us to look to technology for help with irrigation:

- Acquiring sustainable irrigation water supply;

- Uniformly distributing water and nutrients to the crop;

- Proper timing and amount of irrigation for optimal production;

- Irrigating with limited labor yet improving execution and precision;

- Optimizing water and energy costs in relation to crop revenues; and

- Protecting groundwater and surface water from non-point source pollution.

On the other hand, there can be a variety of constraints to adopt irrigation technology:

- Technology is available from many origins, in many forms and intensities. Because of this, it comes with a potentially steep learning curve to identify and understand whether a technology fits the need(s).

- No two farms are the same. Each has its unique challenges depending upon the variables (size, crops, human resources, microclimate, soils, water source, etc.).

Where to Begin?

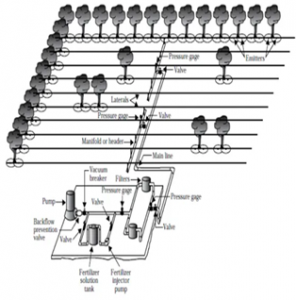

When considering new irrigation technology, it’s probably best to start from the familiar “30,000 foot” perspective. An orchard irrigation system has multiple components (Figure 2) and it’s necessary to determine what aspect may be the weakest link and provide the biggest return to investment in technology. It’s helpful to recognize all of the components and not overlook something as you prioritize needs.

Figure 2. Schematic showing orchard irrigation system beginning with the well and pumping plant and extending out to the last lateral line and sprinkler or dripper.

Water Well Technology

Well design and construction choices affect how efficiently water enters the well from the aquifer. The less efficiently water enters into the well the deeper the pumping water level and the greater the yearly energy bill.

If you are developing and securing a new groundwater supply, seek information on different techniques of well drilling, well design, construction and development. This can lead to a more reliable and affordable water supply and improve your understanding of the well you are buying. Some information resources include: 1) Water well design and construction, UC ANR Publication 8086; and 2) Water well design, construction, and development: Important considerations before making the investment.

Pumping Plant Technology

Overall pumping plant efficiency affects the cost of pumping water. The higher the efficiency, the lower the cost of pumping an acre-foot of irrigation water. Efficiency and cost of pumping are affected by power demand, flow rate, irrigation system pressure, and fluctuating groundwater pumping levels. Flow meters to measure pump flow, pressure gauges or transducers that track irrigation system pressure, and well sounders or sensors to watch pumping levels are available to monitor pumping plant performance and costs (Figure 3). If used, they can notify the operator when the pumping plant performance is veering too far from optimal and is in need of attention. They may also alert a manager of unexpected irrigation system failures such as a pump not turning on or off, or a valve not opening or closing as expected. Other technologies such as solar arrays and variable frequency drives (VFD) are also becoming more common to manage the costs of pumping water. A solar system provides an alternative, renewable power source and a variable frequency drive (VFD) regulates the power to an electric motor to optimize demand and pumping plant performance (Figure 3). This is particularly valuable to manage irrigation sets of different sizes and flow needs. VFD’s improve consistency of flow and pressure to an irrigation system during pump start-ups, back flushing, and when pumping water levels fluctuate.

Figure 3. Magnetic flow meter (upper left), pressure transducer (upper right), acoustic groundwater level sensor (lower left), and VFD digital control panel (lower right).

Irrigation system technology

A wide range of technology is available and all aim to grow uniform orchards that produce efficiently and at a high level for many years. This includes orchard site preparation schemes, choices among water filters, pressure regulators, drip emitters, microsprinklers, or minisprinklers, and tools to help monitor and maintain irrigation systems.

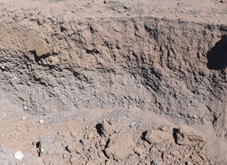

Land assessments using backhoe pits (Figure 4) to guide soil modification with excavators or other deep tillage equipment is one technique used prior to planting trees and installing an irrigation system. Another approach uses non-invasive techniques to map and geo-reference the soil variability. This information is used to precisely design irrigation systems so that soils with distinctly different water infiltration and water holding characteristics can be irrigated in separate sets. This approach is referred to as variable rate irrigation (VRI) or zone irrigation. Refer to UC ANR Publication 3507, Prune Production Manual, Chapter 8 and zone irrigation management articles found on the Sacramento Valley Orchard Source.

It is becoming easier to collect and analyze pressure and flow data from an irrigation system. Pressure gauges or transducers (Figure 5) can be installed in drip or microsprinkler lines intermittently across an irrigation system to verify the system is operating as designed and according to schedule. This allows a quick response, if needed, or the option to save the historical data for later management review. Small flow meters can also be installed on injection pumps to verify chemigation and fertilization efforts are going as planned.

Irrigation scheduling technology

Decisions on when to begin irrigating, how frequent and long to irrigate, and when to stop irrigating an orchard is often based on experience. However, there is growing interest in information and technology that enables a manager to adjust to site specific weather, soil, and crop conditions (Figure 6). The technology varies considerably ranging from manually operated, partially automated, or fully automated. The delivery of information can range from infrequent snapshots in time to hourly or more frequent delivery so that trends in crop water balances, soil moisture, or tree water status can be observed, evaluated, and used to guide the next irrigation scheduling decision.

Figure 6. Irrigation scheduling technology. ET station (top left), plant water status sensor (top right), and soil moisture sensor (bottom).

Remote data and information acquisition

Remote implies “from afar” and not actually being there in person. Data acquisition is a process of collecting signals from various sensors that measure real-world physical conditions. “Telemetry” (Figure 7) is the means of gathering and transmitting the data to a collection point. After the signals are received they are then converted to useful numerical values that can be analyzed on a computer and interpreted to answer questions and guide management decisions.

Figure 7. Parts of a telemetry system. Cell tower and gateway next to pump controls (top left), gateway connection to internet (bottom left), orchard cell tower connected to sensors in the field (top right); and node connection to field sensors (bottom right).

Being able to collect quantitative data and information and respond based upon it while reducing labor and management time spurs interest in irrigation technology. It represents opportunity and hope as we strive to irrigate orchards as efficiently and productively as possible.

Find your place on the technology continuum

Irrigation technology is best viewed as a “continuum”… something that changes constantly but gradually without clear dividing points. It will continue to have a level of uncertainty and choosing to pursue technology is not always necessary, rather it is contingent on need.

When considering irrigation technology, it’s probably best to step back and try to view the irrigation system in its entirety. By doing this, it will provide an opportunity to appreciate the improvements that have already been made and identify those parts of the system that are in greatest need of attention in the future. This should help ensure investments are focused on improvements with less risk and the largest opportunity for return.

Once some needs have been identified and prioritized, it may make sense to try the technology on a partial scale or even manually to establish proof of concept, robustness, and effectiveness on the way towards automation and broader adoption.

Leave a Reply